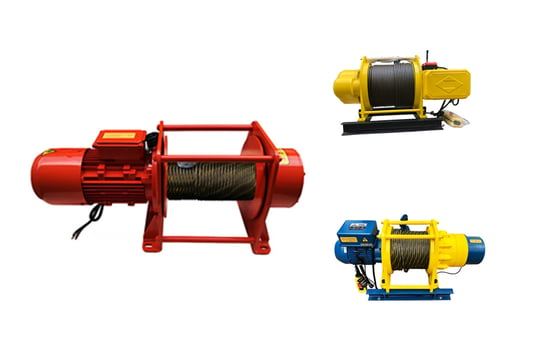

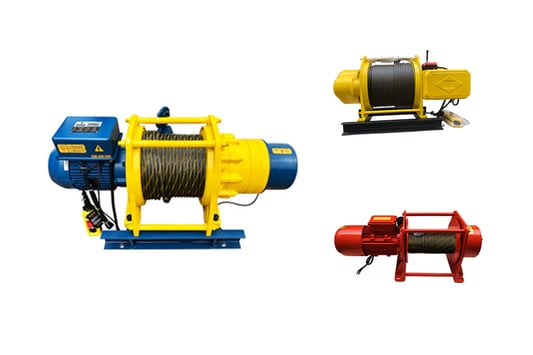

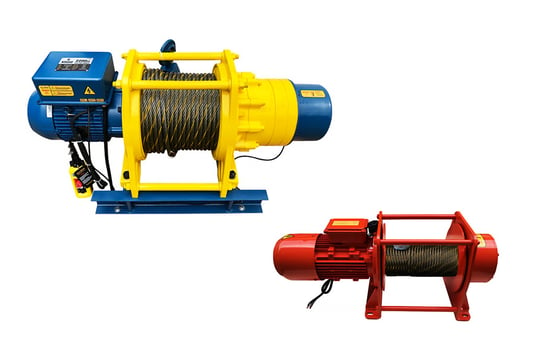

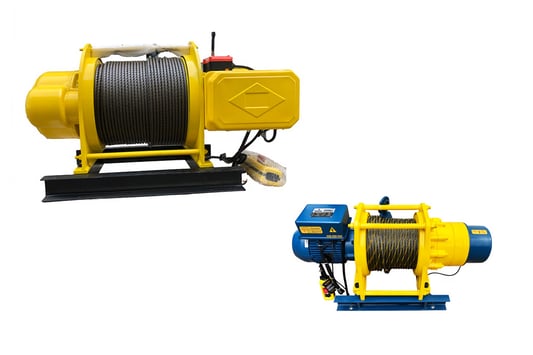

Introduction to 1 Ton Heavy Duty Electric Winches A 1 ton heavy duty electric winch is a powerful tool designed for lifting, pulling, and positioning heavy loads up to 2,000 pounds. These winches combine electric motors with durable construction to deliver reliable performance in industrial, automotive, and construction applications. Understanding their capabilities is essential for selecting the right winch to meet specific heavy-duty needs.Core Components and Build Quality The 1 ton heavy duty electric winch features a robust steel or aluminum housing, a high-torque electric motor, and a strong steel cable or synthetic rope. Its build quality emphasizes durability and longevity, ensuring it withstands harsh environments and heavy use. Key components such as the clutch, gearbox, and drum are engineered for efficient load handling and smooth operation.Power Source and Electrical Specifications Most 1 ton heavy duty electric winches operate on 12V or 24V DC power, often drawing electricity from vehicle batteries or dedicated power supplies. The electric motor’s amperage rating and voltage determine pulling speed and torque, important factors for users to consider when matching the winch to their power source and load requirements.Load Capacity and Safety Margins While a 1 ton rating standardizes the maximum safe working load at around 2,000 pounds, most heavy duty electric winches include built-in safety margins to prevent overload. Operators must respect the rated capacity and use proper anchoring techniques to maintain safety and avoid equipment damage.Versatile Applications of 1 Ton Heavy Duty Electric Winches These winches serve a variety of industries such as automotive recovery, boat launching, construction site lifting, and material handling. Their moderate load capacity makes them ideal for medium-duty tasks where precise load control and portability are required without the complexity of larger industrial winches.Installation and Mounting Options Installing a 1 ton heavy duty electric winch typically involves mounting it on trucks, trailers, utility vehicles, or fixed structures. The winch’s compact and modular design facilitates integration with commonly used mounts and accessories like hawse fairleads or roller fairleads, enhancing cable management and durability.Control Mechanisms and User Interface Modern 1 ton heavy duty electric winches often feature remote controls, allowing operators to manage pulling or lifting from a safe distance. Wired and wireless remotes vary by model, but both improve operational safety and convenience, reducing the need for direct manual handling of the cable or motor.Maintenance Requirements for Longevity Proper maintenance is vital to preserving the lifespan of a 1 ton heavy duty electric winch. Regular tasks include inspecting the cable or rope for wear, lubricating moving parts, checking electrical connections, and testing the brake system. Routine upkeep minimizes downtime and costly repairs.Comparing Synthetic Rope vs Steel Cable Options Many 1 ton heavy duty electric winches offer the choice between synthetic rope and steel cable. Synthetic rope provides lighter weight and easier handling, reducing injury risk, while steel cable is more abrasion-resistant and cost-effective. Users should assess their usage environment to choose the most suitable option.Cost and Value Considerations Price ranges for 1 ton heavy duty electric winches vary based on motor efficiency, build materials, brand reputation, and included accessories. Investing in a quality winch balances upfront cost with reliability, safety features, and warranty support, ultimately delivering greater value and performance over time.Quote Inquirycontact us