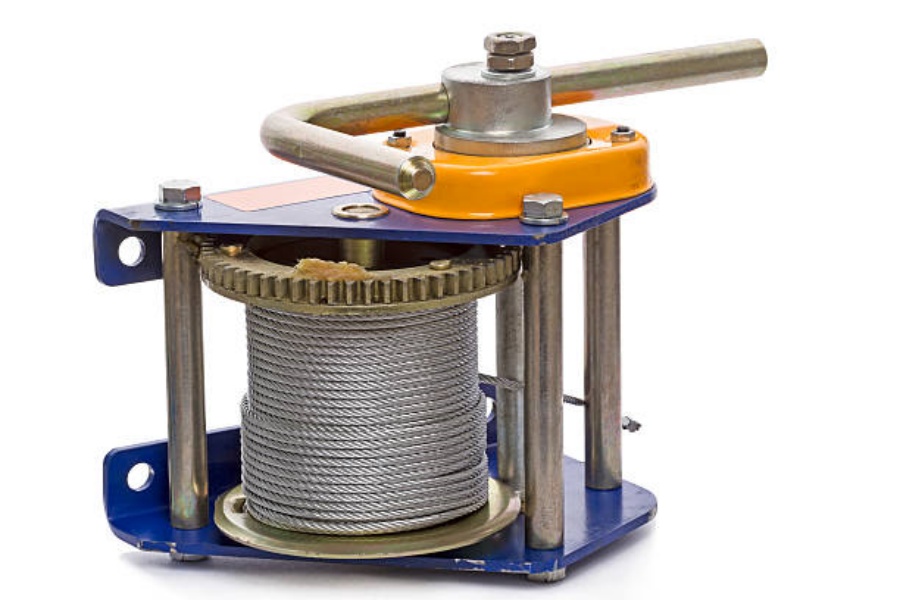

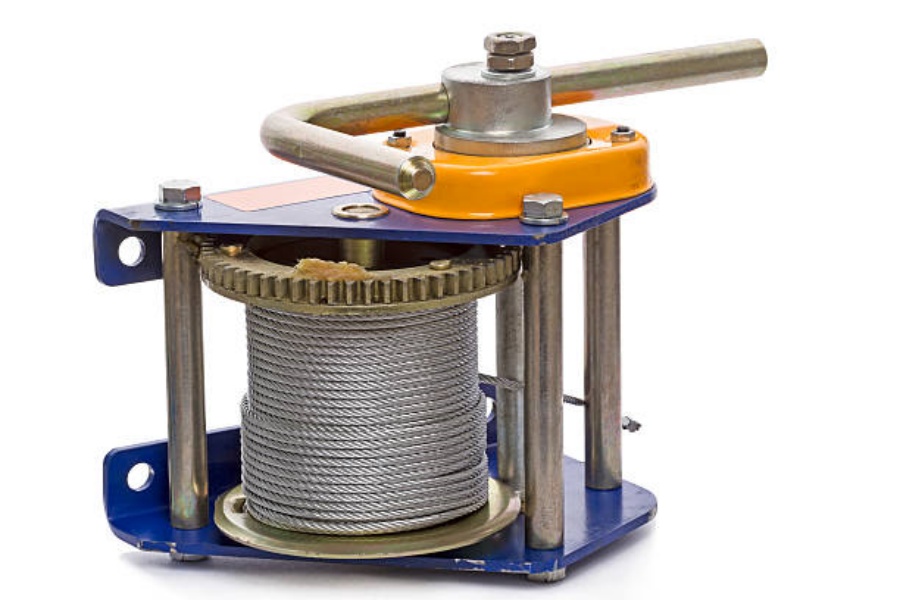

Understanding the Importance of Regular BHW Winch Maintenance

Maintaining a BHW winch is crucial to ensure its longevity and reliable performance. Regular maintenance prevents unexpected breakdowns, enhances safety during operation, and reduces repair costs. Given the winch’s role in heavy-duty lifting and pulling tasks, neglecting routine care can result in mechanical failures that compromise both equipment and user safety.

Inspecting the BHW Winch Cable for Wear and Damage

One of the primary focuses in the

BHW Winch Maintenance Guide is the thorough inspection of the cable or rope. Look for fraying, kinks, corrosion, or broken strands that can reduce cable strength. Damaged cables are unsafe and should be repaired or replaced promptly to prevent accidents and maintain optimal winching performance.

Lubrication Practices Tailored for BHW Winches

Proper lubrication is vital to reduce friction between the moving parts of a BHW winch. Use manufacturer-recommended lubricants on gears, bearings, and the cable drum. Regular lubrication prevents rust formation and prolongs mechanical efficiency, ensuring smooth operation even under heavy loads and harsh environmental conditions.

Cleaning and Debris Removal for Optimal Winch Functionality

Dirt, dust, and debris can accumulate on the winch components, leading to accelerated wear and corrosion. This maintenance step involves cleaning the winch after each use, especially if it has been exposed to mud or saltwater. Using a soft brush and mild detergent can aid in keeping the winch components clean and functioning properly.

Checking the Electrical Connections and Controls

The electrical system in a BHW winch requires routine checks to ensure consistent power delivery. Inspect the battery terminals, wiring harness, and control switches for corrosion, loose connections, or damage. Maintaining the electrical components ensures that the winch’s motor operates at optimum efficiency and reliability.

Testing the Brake System for Safety Assurance

The winch brake is a critical safety feature that prevents uncontrolled spool-out of the cable. The maintenance guide emphasizes frequent testing of the brake’s function, including the mechanical brakes or electric braking systems. Any signs of weakness or failure require immediate attention and repair to uphold operational safety standards.

Evaluating Gearbox Health and Fluid Levels

The gearbox in a BHW winch transmits power to the drum and requires proper care. Regularly check the gearbox oil or grease levels and replace them according to the maintenance schedule. Inspect gears for signs of wear or damage, as faulty components can lead to power loss or winch failure during demanding operations.

Storage Tips to Preserve BHW Winch Integrity

Proper storage when a winch is not in use helps maintain its condition. Store the BHW winch in a dry, sheltered location to prevent moisture accumulation, which leads to rust and corrosion. Covering the winch with a protective tarp or case further shields it from dust and environmental damage.

Scheduling Professional Inspections and Repairs

While routine owner maintenance is essential, periodic professional inspections enhance the longevity of the BHW winch. Skilled technicians can identify subtle issues that may be overlooked and perform necessary repairs or part replacements. Following professional check-ups prevents expensive breakdowns and ensures compliance with warranty requirements.

Documenting Maintenance Activities and Frequency

Keeping detailed records of all maintenance activities, such as inspections, lubrication, cleaning, and repairs, forms an important part of the BHW Winch Maintenance Guide. This documentation helps owners track the winch’s condition, schedule timely upkeep, and validate service history for resale or warranty claims. Consistent record-keeping also supports best practices for safety and performance management.

Quote Inquiry

contact us